motor lamination steel

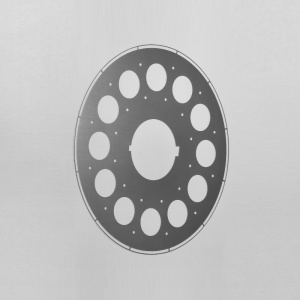

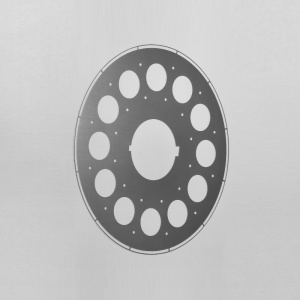

Motor Lamination Steel: Key Properties and Applications Motor lamination steel, also known as electrical steel or silicon steel, is a specialized material used in the cores of electric motors, transformers, and other electromagnetic devices. Its unique properties enable efficient energy conversion by minimizing energy losses, making it indispensable in modern electrical engineering. Composition and Types Motor lamination steel is primarily made of iron with added silicon (typically 1–3.5%), which increases electrical resistivity and reduces eddy current losses. The material is classified into two main types: 1. Non-oriented (NO) Electrical Steel – Used in rotating machines like motors and generators, where magnetic flux direction changes continuously. It has isotropic magnetic properties. 2. Grain-oriented (GO) Electrical Steel – Designed for transformers, where magnetic flux flows predominantly in one direction. It offers superior magnetic performance in the rolling direction but is less suitable for motors. Key Properties - Low Core Losses – The addition of silicon reduces hysteresis and eddy current losses, improving efficiency. - High Magnetic Permeability – Ensures effective magnetic flux conduction with minimal energy waste. - Thin Lamination Thickness – Typically ranges from 0.1 mm to 0.65 mm; thinner laminations further reduce eddy currents. - Insulated Coatings – A thin insulating layer (e.g., phosphate or oxide coating) prevents interlaminar short circuits. Manufacturing Process The production involves: 1. Cold Rolling – Reduces thickness and enhances grain structure. 2. Annealing – Heat treatment optimizes magnetic properties by relieving internal stresses. 3. Coating Application – Insulating layers are added to minimize eddy currents. Applications Motor lamination steel is critical in: - Electric Motors – Used in automotive (EVs), industrial, and household appliances. - Generators – Ensures efficient energy conversion in power plants and renewable energy systems. - Transformers – Grain-oriented variants are preferred for static energy transfer. Advancements and Trends Ongoing research focuses on: - High-Strength Alloys – For applications requiring mechanical durability. - Amorphous and Nanocrystalline Materials – Offering even lower core losses. - Sustainability – Recycling and eco-friendly production methods are gaining importance. Conclusion Motor lamination steel plays a vital role in enhancing the efficiency and performance of electromagnetic devices. Its optimized magnetic properties, combined with advanced manufacturing techniques, ensure minimal energy losses, supporting the global shift toward energy-efficient technologies. As demand for electric vehicles and renewable energy grows, the development of superior lamination steels will remain a key focus in material science.

Products

Category:

-

Laser Cut Motor Laminations

Category: Punching and Bulk FilmBrowse number: 43Number:Release time: 2025-09-30 11:02:35Laser Cut Motor Laminations: Precision, Efficiency, and Applications in Modern EngineeringThe manufacturing of electric motors relies heavily on the quality and precision of their core components, particularly the laminations that form the stator and rotor. Among the various methods used to produce these laminations, laser cutting has emerged as a leading technology due to its accuracy, flexibility, and efficiency. This article explores the significance of laser cut motor laminations, their advantages over traditional methods, and their applications in modern engineering. 1. Introduction to Mo... -

Insulated Motor Laminations

Category: Punching and Bulk FilmBrowse number: 45Number:Release time: 2025-09-30 11:29:22Insulated Motor Laminations: A Comprehensive Guide IntroductionInsulated motor laminations are a critical component in the construction of electric motors, transformers, and other electromagnetic devices. These laminations are thin sheets of electrical steel stacked together to form the core of the motor, reducing energy losses and improving efficiency. The insulation between the laminations is essential to minimize eddy currents, which can lead to heat generation and reduced performance. This article explores the importance, manufacturing process, materials, and applications of insulated moto...

News

Category:

-

[FAQ]What is Motor Lamination and Why is it Important

2025-09-30 15:59:00 -

[FAQ]Motor Lamination Stacking Methods and Benefits

2025-10-07 17:06:46

Case

Category:

No search results found!

Video

Category:

No search results found!

Download

Category:

No search results found!

Job

Category:

No search results found!

Featured Products

No search results found!

Mobile: +86 13738592999

Mobile: +86 13738592999 Telephone: +86(576) 89307999

Telephone: +86(576) 89307999 E-mail: sales@zjxinzheng.com

E-mail: sales@zjxinzheng.com Address: Coastal Industrial City, Sanmen

Address: Coastal Industrial City, Sanmen

WhatsApp

WhatsApp Phone

Phone